Grupo gámiz

A company with deeply rooted values

Innovation, technology, quality and sustainability

Only then could a humble sawmill become the first manufacturer in the world to make hardwood glulams.

Today, Grupo Gámiz is a consolidated, highly valued partner for all companies that use quality wood in their processes: industry, construction, architecture, interior design…

- INNOVATION is the only way to learn to improve

- Cutting-edge TECHNOLOGY helps us do this

- QUALITY is not a given, it’s certified

- SUSTAINABILITY is the only option

How do we do it?

1. The sawmill

It all started here. At our sawmill in Kanpezu (Álava, Spain).

And we’re still here. The primary processing of the wood that arrives at our facilities happens at the sawmill.

From here, some products come out finished and others are used to make secondary processed products.

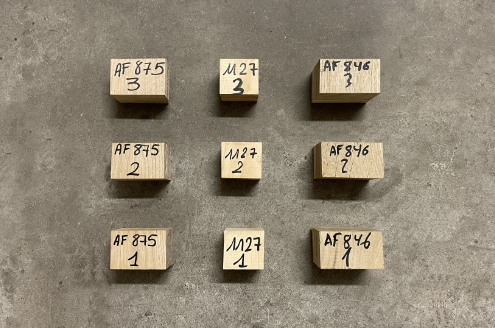

2. Laboratory

The R&D&I experts at our laboratory research different raw materials, processes and applications.

The most successful results, which help companies that use wood evolve, will be made into real products in the glulam plant.

3. Glulam plant

At this plant we manufacture the secondary processed products.

Beams, scantlings, boards…

Products backed by the most important certifications in quality and of course, sustainability.

Our strategy to ensure sustainability is to seek out the wood we use to manufacture our products within a radius of 400 km

HISTORY OF GRUPO GÁMIZ

Building a world of quality wood since 1942

1942

Maderas Gámiz started out as a company dedicated to forestry, coal extraction and the commercialization of timber.

1957

The first sawmill was set up in Santa Cruz de Campezo.

1970

Another sawmill was acquired. The scope of action of Maderas Gámiz grew with the beginning of the manufacture of parquet and the veneer production process.

1990

A new sawmill was installed and new production methods and more advanced techniques were introduced.

2001

A great qualitative leap took place, by starting to manufacture more elaborated, innovative and high-added value wood products.

2002 – THE PRESENT

GRUPO GÁMIZ continues to advance continuously, implementing new technology and new machinery, and bringing new products to the market. Obtaining quality certificates and the importance of the R&D+i department mark the profile of the group and outline the lines along which the future of the company will be strengthened.

THE COMPANIES THAT FORM GRUPO GÁMIZ

Unity is strength, in addition to the best customer service

GÁMIZ MANUFACTURED

This is the company with the highest added value in the group. The sawmill is located here, with the capacity to process 40,000 m3 per year of European oak, American red oak, beech, ash and other hardwoods.

In addition to the first transformation, the company also has a second transformation plant, which together with its R+D+i department, specialises in the development and manufacture of laminated profiles (PERFIGAM), laminated boards (ALIGAM) and laminated beams (VIGAM).

Although their speciality is hardwood species, they also work with other woods such as iroko or radiata pine from the Basque Country (coniferous). They are also official distributors of ACCOYA® acetylated wood in Spain.

GÁMIZ ZÚÑIGA WOODS

It exclusively commercializes premium high quality products, such as exclusive composites and high-tech flooring. Exclusive distributors for Spain of GEOLAM Wood Plastic Composite (WPC), and its new product, GEOLAM Premium Wood Hybrid System (WHS), profiles that combine composites with aluminium, manufactured by the company EINWOOD (Japan).

We are the manufacturer of the world’s only oak glulam with structural CE marking.

CE certificates

GRUPO GÁMIZ is the first manufacturer worldwide to obtain the CE marking for structural use of oak glulam beams (June 2013). Since then, our manufacturing process is controlled and supervised externally by the prestigious German centre, MPA Stuttgart, Otto-Graf-Institut.

– CE Conformity Certificate Oak

In addition, GRUPO GÁMIZ has recently incorporated glulam beams, using local insignis pine (pinus radiata), premium-quality beams aimed at high demand applications and curtain-wall facades.

CTB certificates

Since the beginning of 2010 GRUPO GÁMIZ has held the prestigious quality certificate of the FCBA (France), CTB-LCA marking, for the elaboration of our oak, beech and pine laminated profiles. This means that, in addition to our own internal controls, our manufacturing process is monitored by this external, independent institute, which guarantees our customers the highest quality in our wood products.

EPD certificates

GRUPO GÁMIZ holds the environmental product declaration, both for VIGAM, oak, beech, ash, iroko and pine glulam beams, as well as for PERFIGAM, oak, beech and pine laminated profiles. The climate declarations show the greenhouse gases emissions, expressed as CO2 equivalents. It is based on the verified results of the life cycle assessments (LCA) developed as a basis for an EPD, in accordance with ISO 14025

PEFC certificates

GRUPO GÁMIZ companies have been PEFC certified since 2005, the most widely implemented forest certification system in the world. The objective of PEFC is to ensure that the world’s forests are managed in a responsible manner.

FSC certificates

Since 2012 GRUPO GÁMIZ has held the FSC® certification (Forest Stewardship Council), an evaluation process to which the forestry company or company voluntarily submits, and which is carried out by an independent certification body through field audits and consultations.